Wood Grinders: Boost Your Operations with Precision and Performance

Wiki Article

Maximize Source Efficiency With High-Quality Wood Grinders for Recycling Procedures

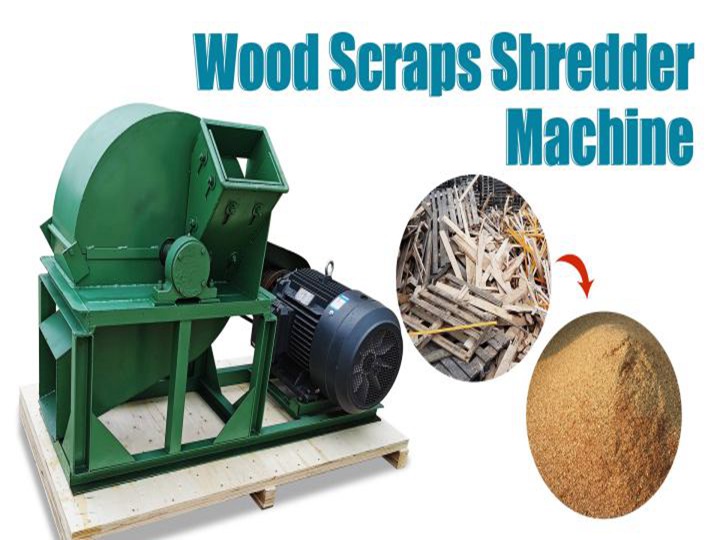

Worldwide of recycling operations, optimizing resource efficiency is a leading priority. One key component to accomplishing this goal is the use of high-grade wood mills. These powerful equipments play a critical function in breaking down wood waste right into smaller, extra workable items, enabling for less complicated processing and recycling. What makes a timber grinder genuinely top quality? And just how can it contribute to maximizing source efficiency? In this discussion, we will certainly explore the significance of timber mills in recycling, look into the numerous types offered, highlight their benefits in source efficiency, and offer pointers for picking the best grinder for your particular procedures. Allow's dive in and uncover just how these amazing machines can revolutionize your recycling ventures.The Importance of Wood Grinders in Recycling

Timber mills play a crucial function in the recycling industry by efficiently breaking down and refining timber waste materials. As the demand for sustainable waste monitoring services continues to grow, timber mills have actually come to be a crucial device for recycling operations. These machines are designed to take care of numerous sorts of wood waste, consisting of pallets, lumber scraps, tree branches, and extra.One of the essential factors why timber grinders are so important in the reusing market is their ability to lower the quantity of wood waste. By damaging down big pieces of timber into smaller, extra workable sizes, these mills create an extra economical and reliable procedure for recycling. This decrease in volume not just saves beneficial garbage dump room however additionally decreases transport expenses associated with transporting bulky timber waste.

Moreover, timber mills assist to boost the general quality of recycled wood products. By efficiently damaging down wood waste, these makers remove pollutants such as nails, screws, and various other pollutants, ensuring that the recycled wood is suitable and tidy for reuse in different applications. This quality control is critical for sectors that depend on recycled timber, such as building, furniture manufacturing, and biomass power manufacturing.

Sorts Of High-Quality Wood Grinders

Numerous kinds of high-grade wood grinders are readily available in the market to meet the particular requirements and needs of reusing operations. These wood grinders are developed to successfully and effectively procedure timber waste, transforming it right into useful sources such as mulch, biomass fuel, or compost.

One kind of wood grinder frequently made use of in reusing procedures is the horizontal mill. This sort of grinder is understood for its capability to deal with big volumes of wood waste and produce a consistent final product. Straight mills are commonly outfitted with an effective engine and a huge grinding chamber, enabling them to process a variety of materials, consisting of entire trees, stumps, and brush.

An additional kind of wood grinder is the bathtub mill. Tub grinders are characterized by their round form and the presence of a bathtub or receptacle where the wood waste is loaded. These mills are usually made use of for processing bulky products such as pallets, building debris, and eco-friendly waste. Tub grinders are recognized for their adaptability and ability to generate a high-quality output.

In enhancement to horizontal and bathtub mills, there are also specialized timber grinders readily available for particular applications. Chipper grinders are made to create timber chips, which are frequently used in the pulp and paper market. Similarly, mulch grinders are made use of to produce compost, which is widely utilized in landscape design and gardening.

Benefits of Making Use Of Wood Grinders in Source Performance

Wood mills supply various benefits for recycling procedures, helping to maximize resource performance and optimize the processing of wood waste. Among the vital advantages of making use of wood grinders is their capacity to reduce the volume of wood waste. By grinding timber waste right into smaller sized, more workable items, wood mills permit enhanced storage and transport performance. This suggests that more waste can be processed and recycled, causing a decrease in garbage dump use and linked costs.One more advantage of timber grinders is their ability to create a regular and top notch final product. Wood waste that is refined via a grinder can be changed into beneficial materials such as wood chips or compost, which can be made click here to find out more use of in different markets, including agriculture, biomass, and landscape design energy production. The regular dimension and structure of the processed material likewise make it much easier to utilize in manufacturing procedures, such as the manufacturing of composite wood items.

Along with making best use of source performance, timber grinders additionally add to ecological sustainability. By recycling timber waste rather than sending it to landfills, carbon exhausts and methane production can be significantly lowered. Furthermore, using wood mills assists to preserve all-natural resources by advertising the use of recycled timber materials instead of collecting new hardwood.

Tips for Choosing the Right Timber Mill for Recycling Workflow

An additional essential aspect to consider is the size and ability of the timber grinder. It is essential to pick a mill that can deal with the anticipated quantity of wood waste without triggering hold-ups or overwhelming the maker. Additionally, the size of the mill ought to work with the readily available space in your facility.

The source of power of the timber mill is also an essential factor to consider. Mills can be powered by electricity, diesel, or hydraulics. Each power source has its very own advantages and drawbacks, so it is vital to choose the one that best fits your operational requirements.

Moreover, it is critical to consider the maintenance requirements of the wood grinder (wood grinders). Seek a mill that is durable and easy to maintain, with available parts and a trustworthy assistance network for servicing and repair work

Finally, think about the safety and security attributes of the timber mill. Try to find functions such as emergency stop buttons, safety guards, and automated shut-off devices to shield drivers and protect against crashes.

Ideal Practices for Optimum Efficiency With Wood Grinders

To ensure optimal efficiency with timber grinders, it is vital to execute a set of ideal methods. These methods can help maximize the effectiveness and efficiency of the grinding process, resulting in greater performance and better high quality result.

Second of all, appropriate feeding techniques should be followed. It is advised to feed the mill slowly and evenly, avoiding straining the maker. This makes sure that the wood is refined successfully and minimizes the risk of jamming or clogging.

In addition, choosing the appropriate display dimension for the desired end item is necessary. Different display dimensions can produce various sizes of wood chips or compost, so it is necessary to choose the one that ideal fits the intended application.

Moreover, operators need to be trained on the correct operation of the timber grinder. This consists of understanding security protocols, running procedures, and repairing techniques - wood grinders. Trained operators can decrease the risk of crashes and optimize the mill's performance

Verdict

To conclude, high-quality timber grinders play a vital role in making the most of source efficiency in reusing procedures. By efficiently lowering and processing wood waste, these grinders add to a more ecologically pleasant and sustainable method to reusing. It is very important to very carefully select the appropriate wood mill for particular reusing procedures, considering aspects such as sturdiness, power, and ability. Following best practices for ideal performance can additionally boost the performance and performance of timber mills in reusing.Timber mills play an look here important function in the recycling industry by successfully damaging down and refining wood waste materials.One of the vital factors why wood grinders are so important in the reusing market is their capability to reduce the quantity of timber waste.Wood mills supply countless advantages for recycling procedures, assisting to make best use of source efficiency and maximize the handling of wood waste. By grinding timber waste right into smaller, extra convenient pieces, timber grinders allow for raised read more storage space and transportation efficiency. Timber waste that is processed via a grinder can be changed into useful products such as wood chips or compost, which can be utilized in numerous markets, including landscape design, biomass, and agriculture energy production.

Report this wiki page